Efficient manufacturing and assembly

A powerful tool for small and large companies engaged in custom, piece and serial production, it will help you make only the products that bring real profit.

Why Managing Manufacturing in ABRA Gen is a Good Idea

Do you want to automate production or assembly management in your company?

Find out more about ABRA Gen features for the

following areas of manufacturing:

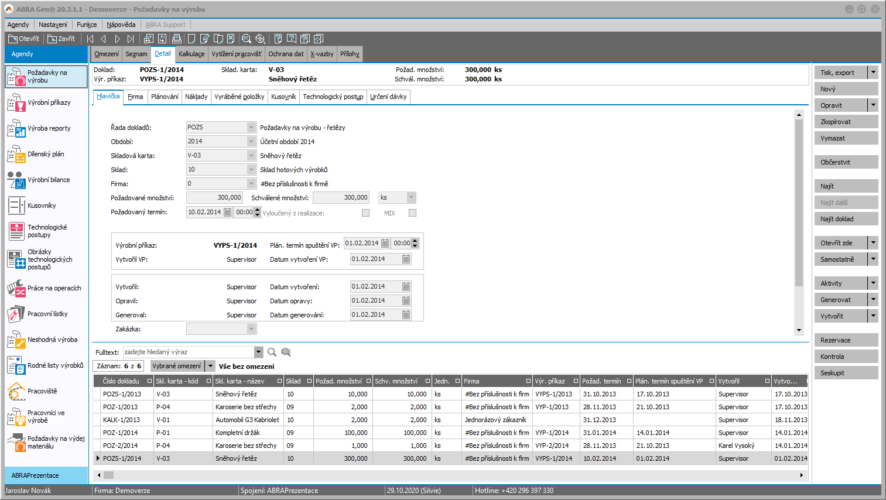

Manufacturing

Avoiding mistakes, maximum use of available resources and no downtime.

- Using production orders, the system comprehensively monitors and controls the entire production process

- The at-cost price of products is calculates as part of your offers

- Fully linked with the warehouse and the option to release and store material directly using bar codes

- Production engineering (PE) support in serial and custom production

- The product’s “birth certificate” can help you track all information about the product; it contains a comprehensive history of production with a link to the production order, link to components, information from the worksheet, etc.

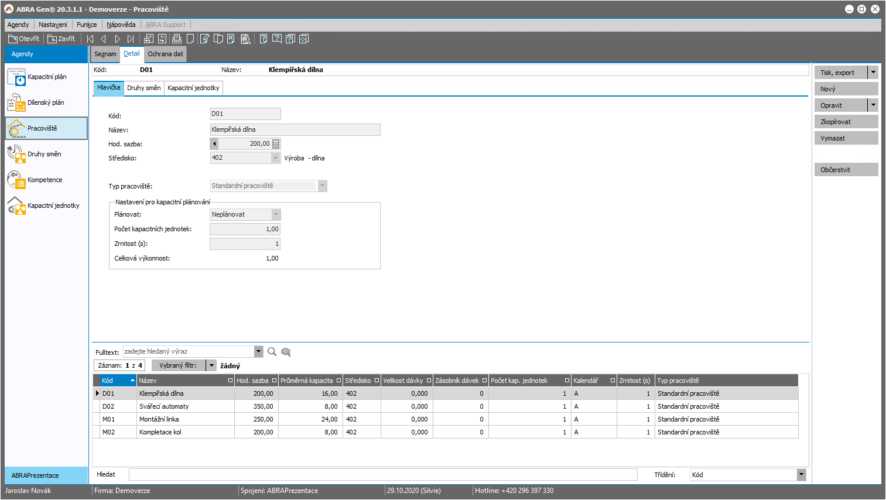

Capacity Planning

The road to efficient manufacturing is through a comprehensive production plan.

- Planning methods – forward and backward, for limited and unlimited capacity, according to material disponibility

- Online data evaluation

- A list documents included in the plan with summary statistics data on the efficiency of the created plan

- The system can carry out smart planning of production processes at the individual work sites

- Work queues can be created in the Workshop Plan agenda; graphic representation of the capacity plan

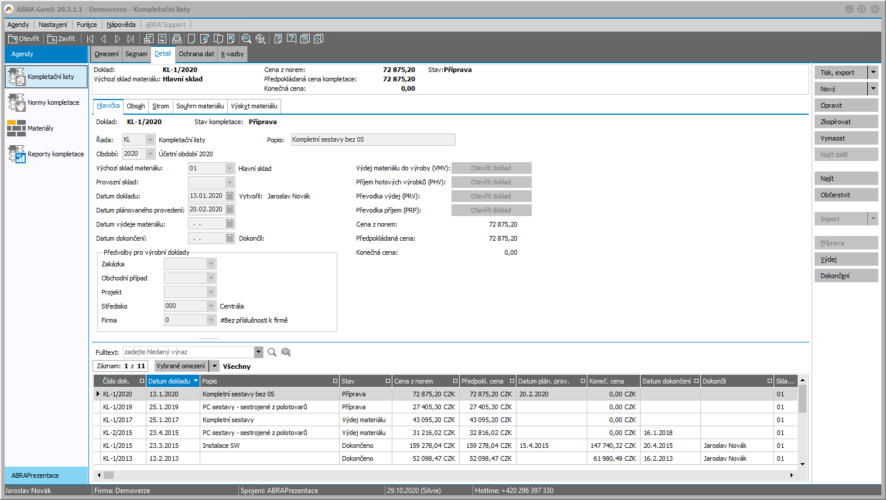

Assembly

Management of the manufacturing of products created by assembling materials and semi-finished products.

- Product assembly takes place in three simple steps – preparation, material issue and completion

- Automatic stocking of material based on stock data analyses by the SCM module or individually, according to the order

- Calculating the at-cost price and comparing it to the actual production price

- For products repeatedly assembled from the same or very similar items, you can define a standard to make assembly as efficient as possible

- A completion sheet can be created from delivery sheets or received orders

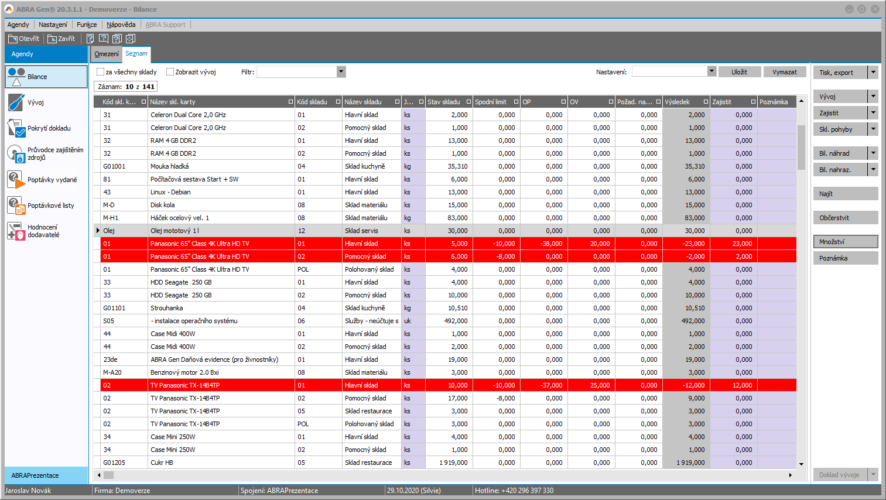

SCM (Supply Chain Management)

Your customers receive their goods on time and there’s no unnecessary idle stock in your warehouse blocking the company’s resources.

- Instant overview of material and goods coverage and minimum stocks

- Optimized future development of stock

- Comprehensive balances combining all available resources, including the monitoring of minimum stock and upper limits of items in stock

- Current and future stock deficiencies warnings

- Fast ordering according to pre-set criteria kritérií

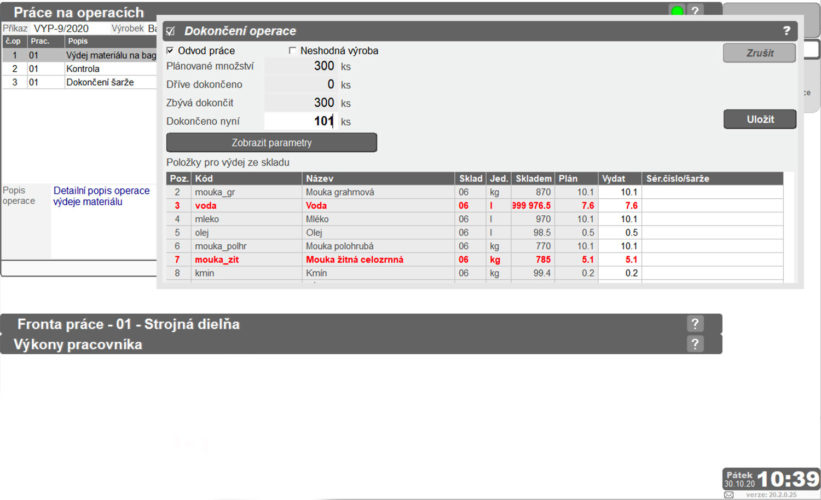

PLM Terminals

A modern tool for efficient production progress records.

- Monitor the time spent on individual operations

- Production data is entered quickly online by reading the bar code of a specific operation; support for batch and serial number tracking is available

- Linking to the warehouse allows automatic write-off of the materials used

- The technology is adapted for touch terminals and supports the printing of production labels

- Records of leftover material, including sheets of sheet metal, plexiglass, etc.

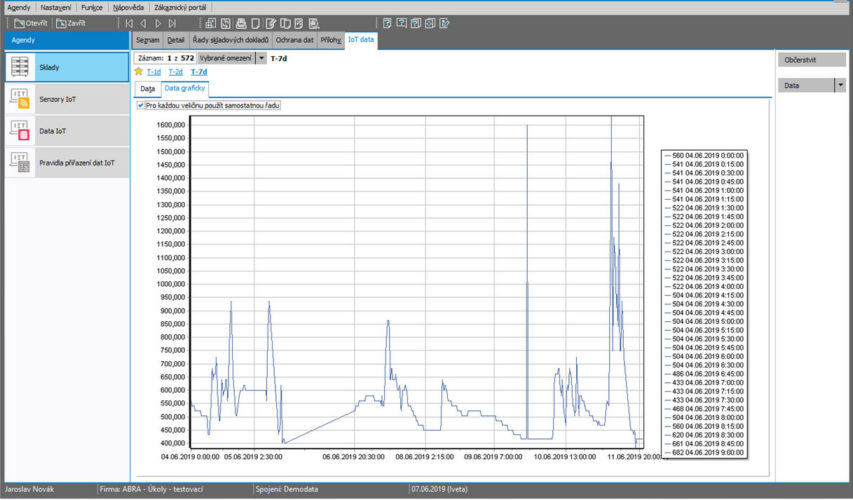

Internet of Things – ABRA IoT Platform

Using sensors and actuators connected via the Internet, your important data can be viewed directly in ABRA Gen.

- Independent from the sensor supplier

- The information is in the system – e.g. a storage card includes a graph of the temperature in the warehouse

- Data from IoT can be analyzed in the information system and put into context with everything that had been entered into it

- Thanks to definable rules, the system can perform automatic steps – lower the temperature in the warehouse, change the air, send notifications to the operator, etc.

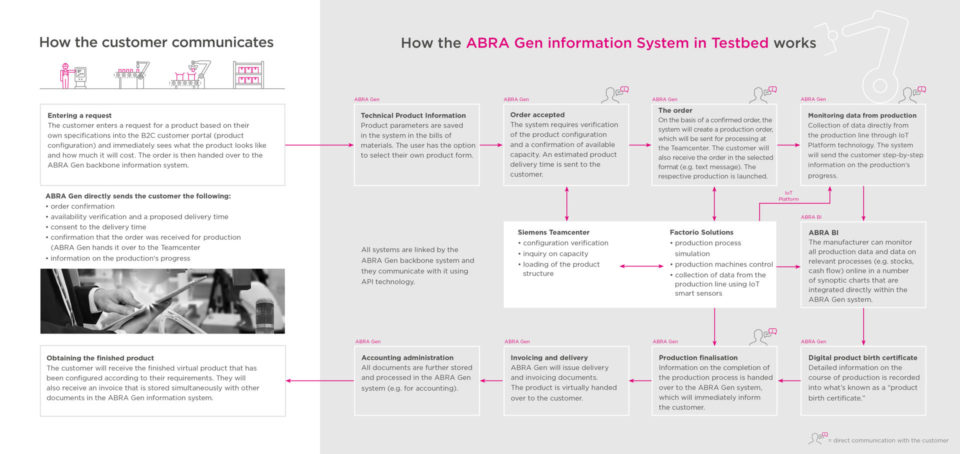

Testbed for Industry 4.0

In the Testbed, companies can simulate the application of technologies in a virtual environment and avoid high costs of deployment in the real world.

- A test environment for innovative solutions for smart companies and their sub-processes

- A flexible production line combining various technologies, including automated warehouses and robotic handling

- So-called digital twins instead of expensive prototypes

- Production technologies are linked with sophisticated control systems

- Save time and costs in production, optimization of operations and procedures

ABRA Software is a founding partner of the National Industry Center 4.0.

Manufacturing as Part of ABRA Gen Solutions for the Company as a Whole

Our All-in-one information system, ABRA Gen, helps you manage your business as a whole. All of your data is in one place, the individual areas of your business are interlinked, and your employees work in a single user friendly interface. Manufacturing is linked with warehouse management and business processes.

References

Are you looking for a cloud-based software for smaller companies and freelance contractors?

Do you need to efficiently manage your production or assembly?

Contact us, we’ll be happy to help.