Grumant

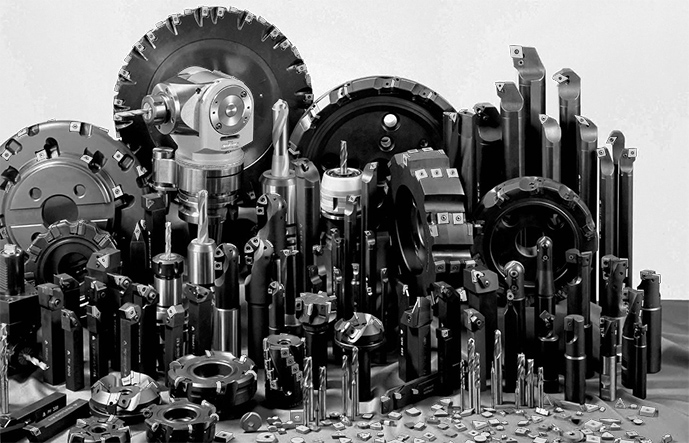

Business company with machining tools and solutions for full support of the machining cycle.

How does ABRA Gen help?

- After the introduction of the information system, the work productivity has grown five-fold .

- One ABRA Business sales representative takes up to 58 orders on a daily basis, processes 30 bids and creates 12 orders totheir suppliers.

- Offers an analysis of all economic and business metrics. So management can analyze the state of the company, create business predictions and plan changes in a few minutes.

- Automates everyday business processes.

GRUMANT s.r.o. is a supplier of technology solutions and tools for full support of the machining cycle. It is a company that broke the outdated view of the concept of productivity in engineering production in the field of deliveries of chip machining tools in the 1990s, and which is currently leading the field with progressive approach and innovation.

Valeri Zakrepa

Founder, Grumant s.r.o.

“Our profit is always and directly connected with the client’s success, because in the case of a clear and open agreement with him, we become not the object of the tender, but a kind of technological division of the client, whose background is also the information system ABRA Gen.”

Grumant has built its 15-year growth on high-quality products, delivery complexity and short delivery times, combined with consistent service and technology support.

In 1993, Ing. Valeri Zakrepa decided to set up a business dealing with high quality machining tools for chip machining. “It was not easy to choose suppliers who excel not only with the high technical quality of the products but also with their reliability. First, we were looking in Russia, but here we hit a wall with reliability, ” commented Valeri Zakrep the beginnings of the company.

SIX YEARS TO SUCCESS

“We have been fighting for the next six years: we have built an assortment from different vendors. The main measure was the quality of the products. We wanted to find mainly suppliers who were not already established in the Czech Republic and who were willing to start trading with a previously unbuilt dealer. We have gradually built one of the widest portfolios of cutting tools and technology in the industry. We now work with about 30 suppliers, from which we always take their TOP products and build their own complete assortment. That is why we can currently offer our clients about 40% lower prices than competitors, with the same or better product quality. Service facilities with reaction time in the order of hours.”

In the 90s, Grumant’s management realized that it was necessary to overcome the profound technological gap with the Western world. Management has begun to promote progressive workflows oriented at results and productivity and to attract young, capable and creative traders. At that time it was necessary to work diligently with the vices of Czech engineering. The client had to understand that a well-chosen modern instrument selected according to the relevant parameters, along with quality process programming and the strategic organization of the machining process, can increase production productivity by tenfold, reduce tool consumption, liquid, electricity, and fixed costs.

THE BENCHMARK OF EVERYTHING IS PRODUCTIVITY

In 1996, Grumant sought new manpower as well as tools to increase productivity. One of these tools eventually became the ABRA Gen information system, which was acquired by the company’s management at the first presentation, where it was made clear that automation will help with many of day-to-day activities.

Thanks to ABRA Gen, business productivity has grown fivefold. Prior to the introduction of the ABRA Gen information system, sales representatives manually issued invoices, delivery notes, and other documents. Once the system has been deployed, one Business Department employee received an average of 58 orders a day, handled 30 bids and created 12 orders to his suppliers, which was previously unthinkable.